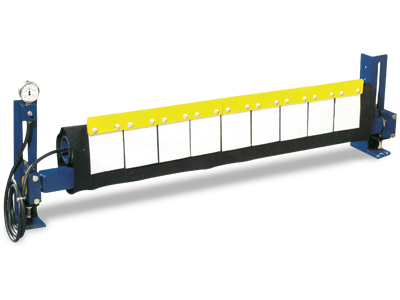

Dirt Whacker

BELT CONVEYOR CLEANER

We manufacture, stock and commercialise worldwide the wonderful conveyor belt scrapers “DIRT WHACKER®”

DIRT WHACKER

- Independent multi-blade modules

- Independent one from another

- Pneumatic suspension and adjustment facilities

- Carbide scraper blades

- Use of "sandwich"-constructed tungsten

DirtWhacker Applications

The Ultimate in Conveyor Belt Cleaning

The DirtWhacker conveyor belt cleaner systems are recognized worldwide for their effectiveness and durability. In addition these conveyor belt cleaners are renowned for their belt-friendliness.

In making use of our proven parallelogram system, the customer is assured that the blade-to-belt angle will always function at the optimum angle.

Our remote control system ensures that the adjustment of the DirtWhacker can be accomplished from a convenient location.

The DirtWhacker Difference

The DirtWhacker Primary Belt Cleaner

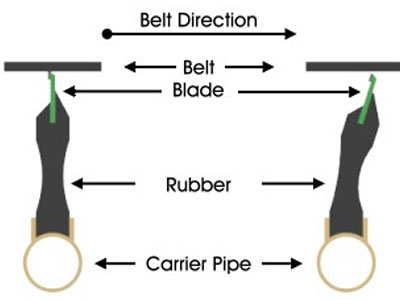

Each of the modules that make up the scraper is based on a 4-greased-joint parallelogram.

– A rubber tube is threaded through the parallelograms to form a bladder in which air pressure can be both applied and adjusted using a foot pump.

– The parallelogram bottom part is welded to a fixed base.

– The side opposite, on which the blade is bolted, is mobile and is able to move tangentially to the belt (as a pantograph would) as a function of the air pressure in the rubber bladder and thus the wear of the blade.

– Each blade operates independently of the other blades as a function of what it receives; the angle of attack remains constant at 90° whatever its position.

– The scraper element is made up of a non-bevelled straight section tungsten carbide blade within a mild steel protection sandwich: total thickness between 6 and 8 mm.

DESIGN HIGHLIGHTS

- The cleaner blades are designed to bring about minimal belt wear to the belt top-cover

- The innovative parallelogram design maintain the optimal belt blade angle irrespective of Blade wear

- The air bladder system ensures even blade to belt pressure over the full cleaner width

- The blade design is compatible with the majority of mechanical belt fasteners

- The unit requires no mechanical adjustment in between blade changes

- At all times there is a visual indication of belt to blade pressure

- The belt to blade pressure can be adjusted from a suitable remote location