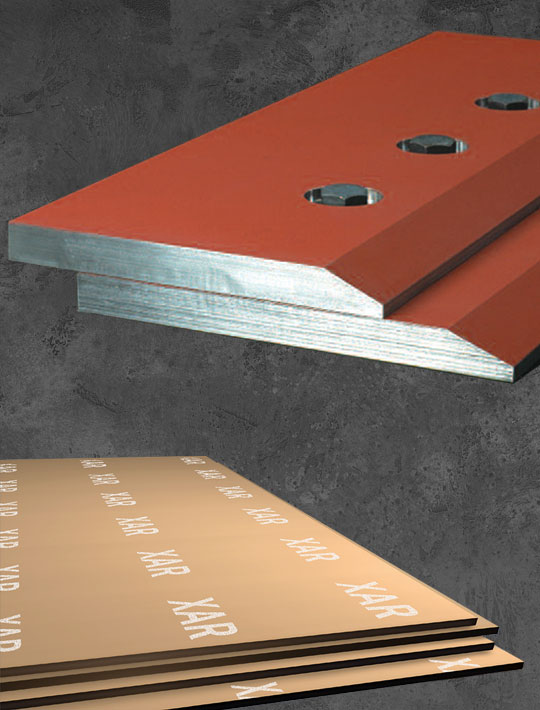

Abrasion resistant steel plates produced by ThyssenKrupp Germany.

Available in : XAR400 – XAR450 – XAR500 – XAR600

Ideal for chutes, bins, cutting edges,…

The XAR quality has an exceptional wear resistance.

Chromium carbide hardfacing overlay plates.

Hardness: 650/700 HB.

Representing one of the most versatile wear resistant materials currently existing. Available in a choice of standard plates sizes typically dim. 3000 x 1500 mm

(or supplied to drawing) and in a choice of thicknesses from 6 up to 29 mm.

produced by THYSSENKRUPP

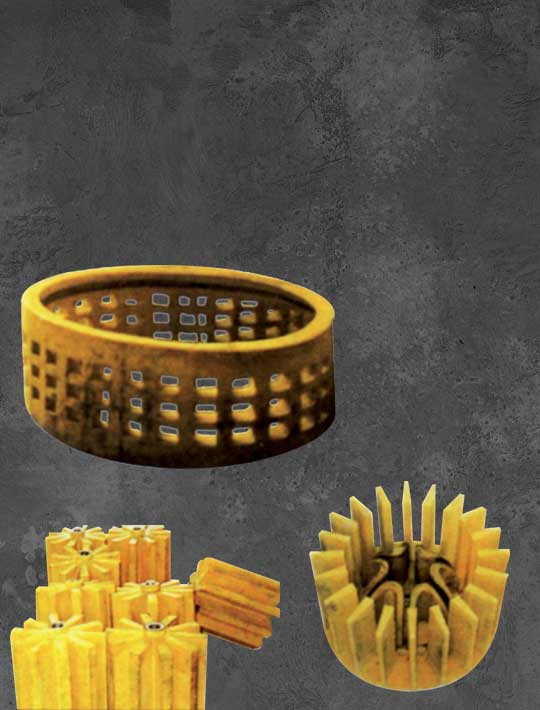

Special tubular construction requiring low operating currents.

Hardness: 650/700 HB.

These electrodes have been engineered to provide extended service life at ambiant and elevated temperatures involving abrasion, erosion, impact and cavitation.

Polyurethanes

All cast parts as per drawing or as per samples.

Polyurethanes

All cast parts as per drawing or as per samples.

These parts offer excellent working performances

not just in abrasion but in impact resistance too.

- Pump parts

- Mill linings and lifting bars

- Screening panels or modules

- Flotation cell wear parts

Polyurethane performs 5 to 6 times better than so-called “wear resistant” rubber.

Absorbs the shock perfectly whilst still resisting the abrasion, this justified its use for the production of screen decks and linings.

Results are much higher compared to classic elastomers with similar hardness; the compression-springs admit loads 3 to 4 times higher.

HMWPE offers both a very good abrasion and impact resistance and sliding properties due to a very low coefficient of friction.

Good chemical resistance.